How economically competitive is industrialised deep retrofit?

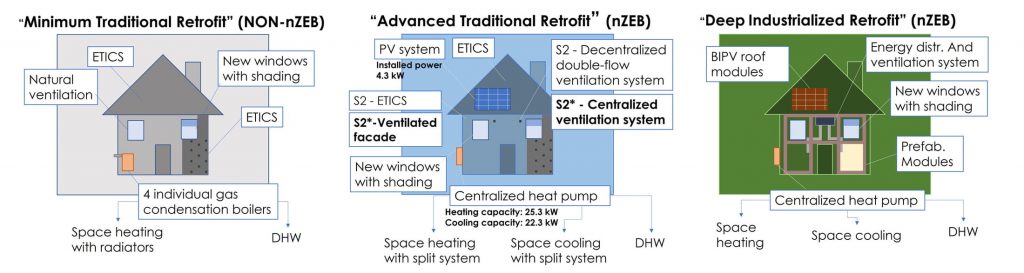

When assessing the cost of industrialised off-site building renovation, often it is compared with the minimum traditional retrofit (non-NZEB). Deep retrofit is usually way more expensive than the minimum retrofit, as the two retrofit have different performances.

Eurac Research instead proposes a comparison between two equally performing retrofits scenarios for an existing building in Italy undergoing a deep renovation. The building examined is the Italian demo case of the project INFINITE.

The advanced traditional retrofit consists of a double flow ventilation system, PV system and centralized heat pump. This retrofit performance is comparable to the INFINITE industrialised deep retrofit to assess the cost difference in a 50-year timespan.

The real costs and a list of bills collected by the design team and the industrialised technologies developers provided the basis to develop the Life Cycle Inventory (LCI) and to perform the LCC modelling for the traditional (minimum) retrofit, the advanced traditional and the industrialised deep retrofit.

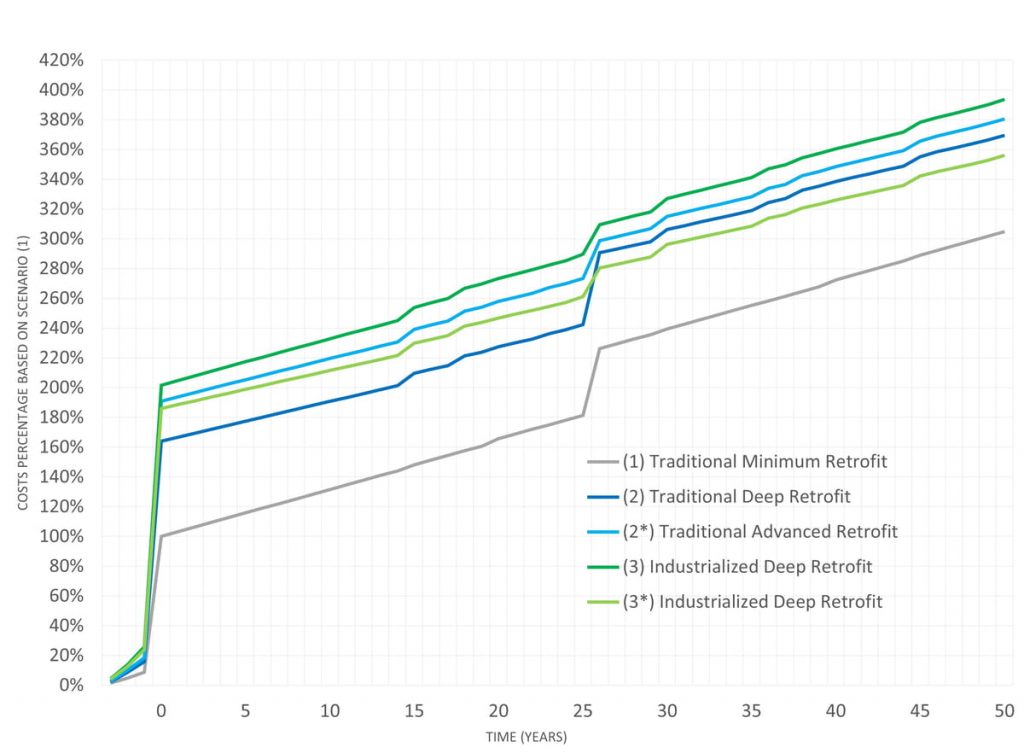

The results are quite promising:

- In 50 years, the two deep retrofit approaches (traditional and industrialised) are comparable in terms of investment costs, even if a gap of around -7% and +16% still exists. There is the possibility to reduce this gap with the market uptake of the technological solutions.

- The operation and maintenance phase are key to transforming the expected higher quality of the industrialised components into a prolonged life expectance: the industrialised deep retrofit requires less interventions and upgrades.

- The analysis of the End of Life phase in case of possible reusing of some dismantled components in the industrialised scenario increases the final value of the industrialised approach.

There are still several steps to be takes to reduce the cost share of the industrialised solutions, in first place the need to reduce the materials used. However, the study shows that there is a high potential to increase the economic competitiveness of deep retrofit actions, reducing the cost gap between the traditional and the industrialized approach to renovate buildings.

The study ” Comparative cost analysis of traditional and industrialised deep retrofit scenarios for a residential building has been authored by Martino Gubert, Stefano Avesani, Jamal Abdul Ngoyaro, Miren Juaristi Gutierrez, Riccardo Pinotti of Eurac Research – Institute for Renewable Energy, and Davide Brandolini of BIT, servizi per l’investimento sul territorio S.P.A.

The scientific article is part of the special edition of the Journal of Facade Design and Engineering. This issue brings together INFINITE and the sister projects ENSNARE and PLURAL, all H2020-funded projects working on the industrialization of building renovation.

RELATED NEWS

Riqualificazione industrializzata: facciate prefabbricate installate a Firenze

Installazione di facciate prefabbricate per la riqualificazione industrializzata in Italia

Industrialised renovation: a successful installation of prefabricated façades

Installation of prefabricated façades in just minutes at the demo building in Greve in Chianti, Firenze

INFINITE at Energiesprong Renovation Days 2024

INFINITE Project at the Energiesprong Renovation Days 2024: showcasing innovative solutions for zero-energy building retrofits